Professional Harness Designing

You only need to share your concept – leave the technical details to us!

Focus on engineering decisions and functional thinking, not on drawing or creating spreadsheets.

We don’t just manufacture Harnesses – we deliver thoughtful, manufacturable design solutions, so you can stay focused on what really matters.

Our professional Harness design service is the ideal solution for partners who require complex harnesses with accurate documentation, fast lead times, and full compliance with industrial standards – whether for new development or modifications to an existing design.

Our experienced engineering team supports you from concept to production.

Ideal for companies that:

- Have no in-house cable manufacturing experience

- Lack of appropriate designing software

- Don’t have capacity to create detailed Harness drawings

Our Real Added Values

- Easy start: You share your requirements – we interpret the technical details and turn them into a manufacturable design.

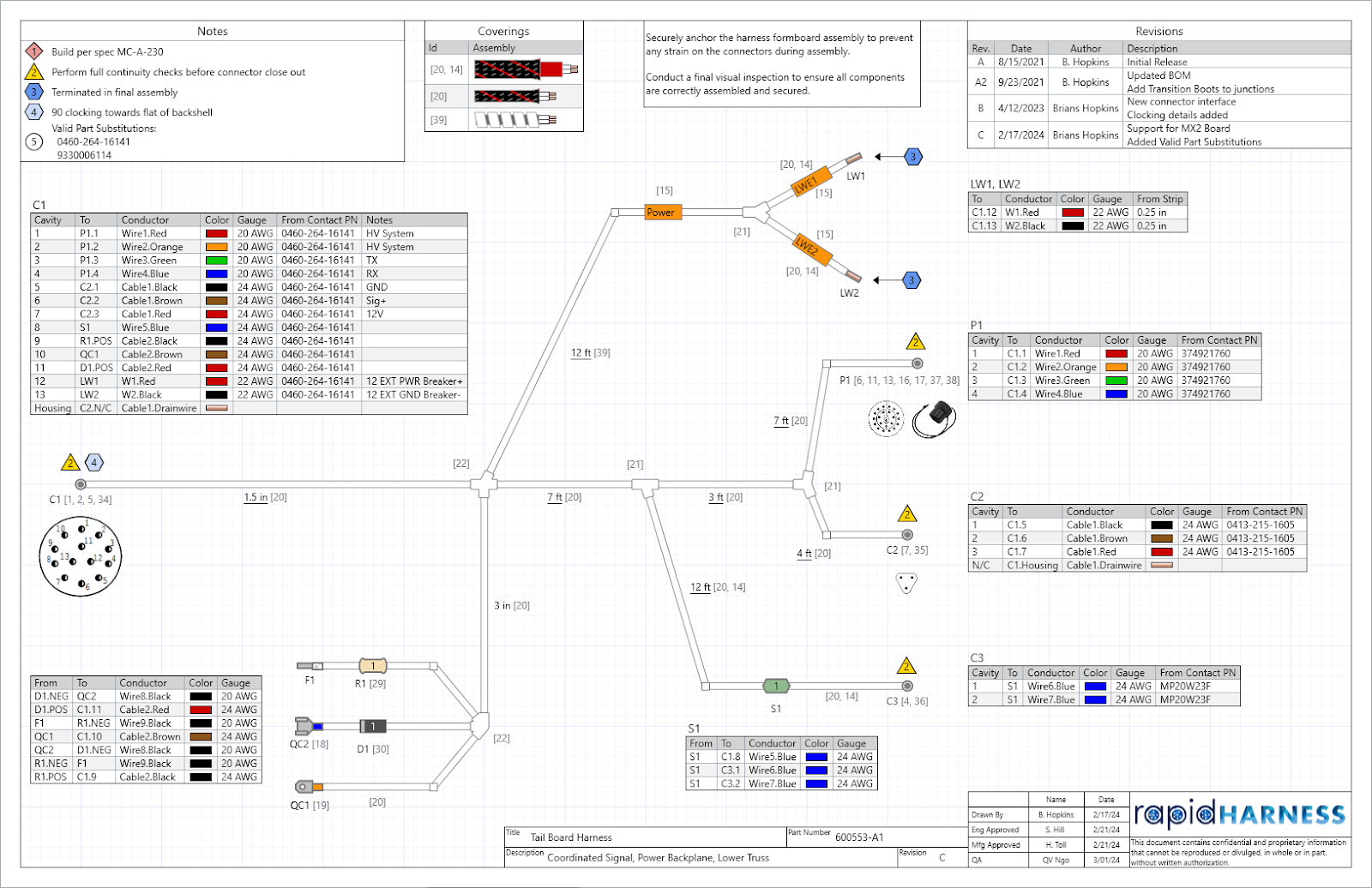

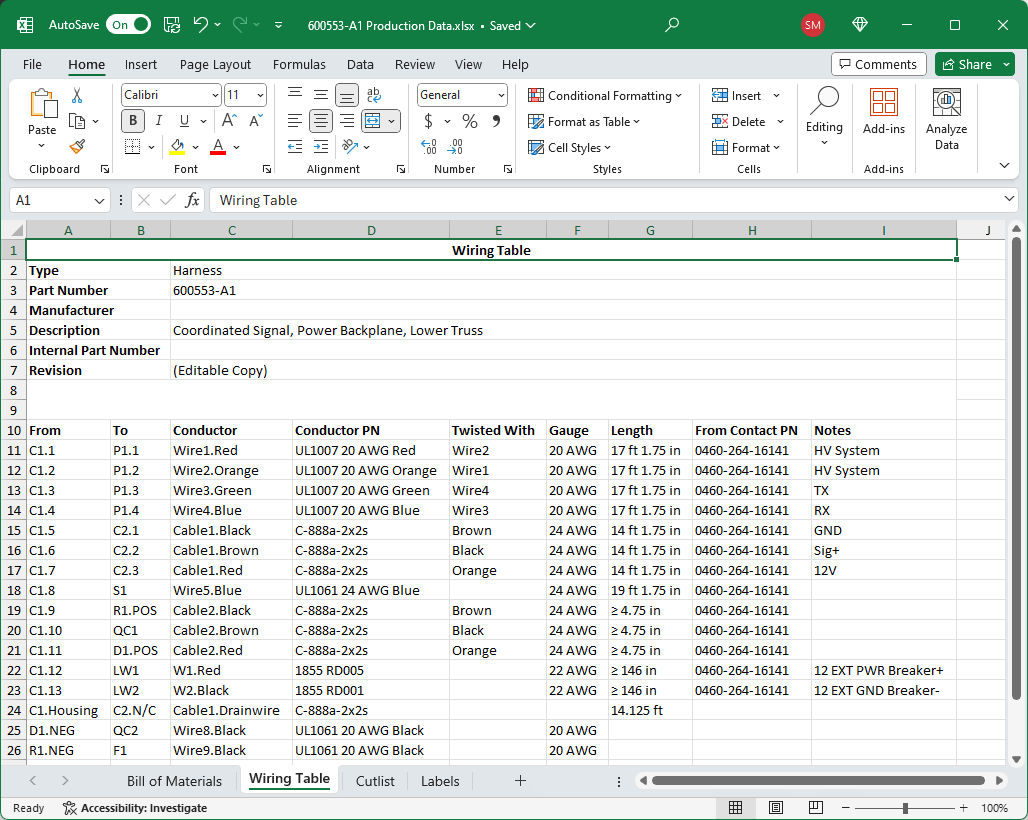

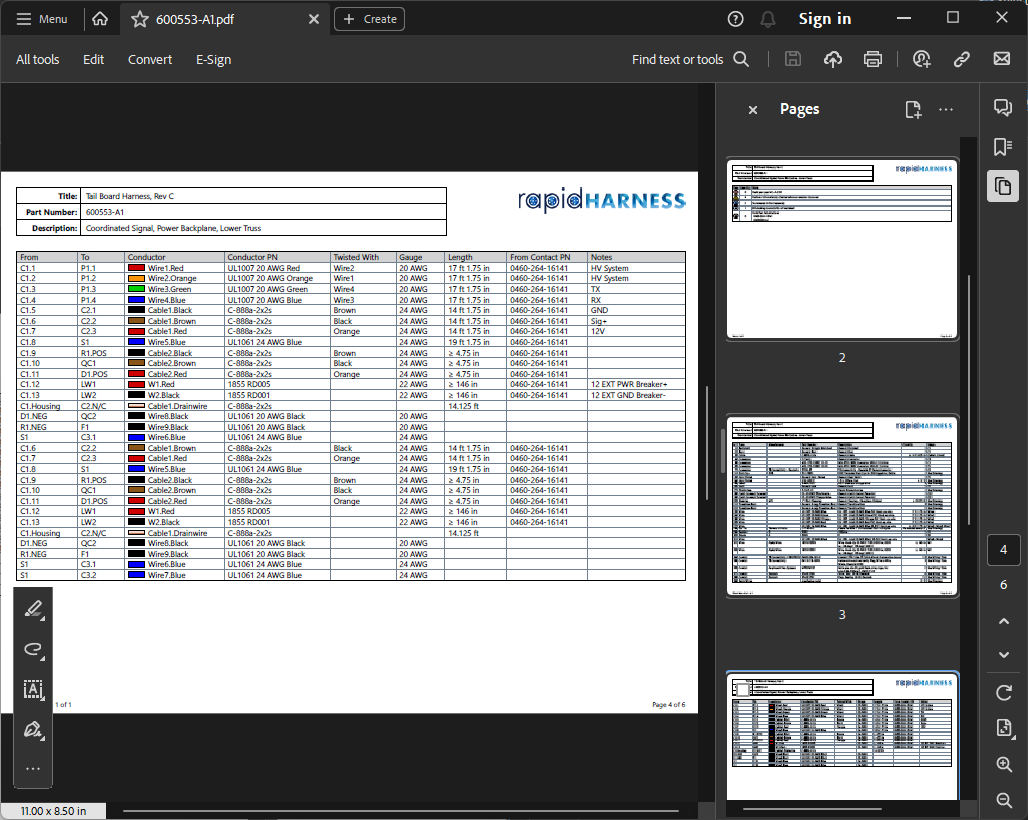

- Production-ready documentation: Our designs automatically include bill of materials (BOM), pinout tables, cut lists, and labeling.

- Cost-effective, error-free solutions: We consider manufacturability, material use, operating environment, and compliance from the very first step. We work according to ISO standards and automotive industry requirements.

- Fast lead time: With automated documentation and a scalable system, your first design version can be ready in just a few days.

- Traceable and version-controlled designs: You can always return to previous versions – allowing full visibility across the entire development process.

You decide, we design: You don’t need to edit drawings and tables – just share the required functionality and environment. We handle the rest.

What Harness design is really about

Harness design is not about drawing lines or arranging the components to look pretty. It’s about:

- Understanding and defining the electrical behavior of the system (what signals go where and how)

- Choosing the right connectors, contacts, wires, shielding, and sleeving

- Considering environmental and safety requirements (e.g. temperature, bend radius, EMC protection)

- Optimizing cost and manufacturability

- Creating a consistent, error-free solution that complies with all applicable standards and end-use requirements

Our team brings over 10 years of manufacturing experience to support you through all of this.

How the Process Works

The Harness design process is simple and transparent:

- Contact us – Reach out via email or by filling out the “Requirement Form” at the bottom of this page, and let us know your project details.

- Initial consultation – We’ll discuss your needs, application environment, requirements, connector types, and available documentation.

- Design phase – We’ll assess component compatibility, material options, and tooling needs. Then we create the first design draft.

- Review & refinement – Based on your feedback, we suggest potential design or material adjustments and fine-tune the design.

- Final documentation – We deliver production-ready drawings and BOMs in your preferred formats.

Lead time: First design version ready in as little as 3–5 business days, depending on complexity.

Harness Design with RapidHarness Software

Our design services are built on the RapidHarness professional CAD platform, developed specifically for production-ready cable assemblies. The system automatically generates full documentation, including 1:1 scale drawings, BOMs, cut lists, labels, and connection tables.

- Automated designs and documentation

- Bill of materials and cut list generation

- Integrated library with over 80 million components

- Full version tracking and team collaboration support

- Export to PDF and Excel – instantly manufacturable

- Flexible, reusable, and scalable design architecture

|

|

|

Requirement assessment form for new projects for the production of custom cables: