Other contents

ROBOT, HUMAN, ROBOT-HUMAN – A Brief History, Present and Future of Humanoid Robots

A transcript of the presentation given by ProDSP for the Bosch ECB Academy on 10th April 2025.

The importance of the golden sample in measurement system validation: the reference sample, the benchmark

In modern manufacturing environments, perfect product quality is a fundamental requirement which can only be ensured through reliable and accurate measurement systems.

Automatic Optical Inspection System (AOI): Modern quality assurance in manufacturing

In modern manufacturing, the emergence of Automatic Optical Inspection (AOI) has brought an innovation that has fundamentally changed the role of quality assurance.

Process Capability Index: Key to manufacturing quality

In modern manufacturing environments, increasing emphasis is placed on process reliability and stability, with the Process Capability Index playing a crucial role in quality assurance.

Cable Connection Leak Testing: Reliable Operation in All Conditions

Cable connections are essential components of electrical and network systems. These devices ensure the smooth transfer of energy, thereby enabling the reliable operation of various electronic devices.

TestStand: the foundation for automated testing

TestStand is a software developed by Emerson/NI to meet automated testing needs.

ISO 9001 certification: the importance for industry applications

ISO 9001 certification is one of the best-known quality management standards and is crucially important for many industrial companies worldwide.

LabVIEW programming: new perspectives in industrial automation

In modern industry and R&D, companies face increasingly complex measurement and automation tasks.

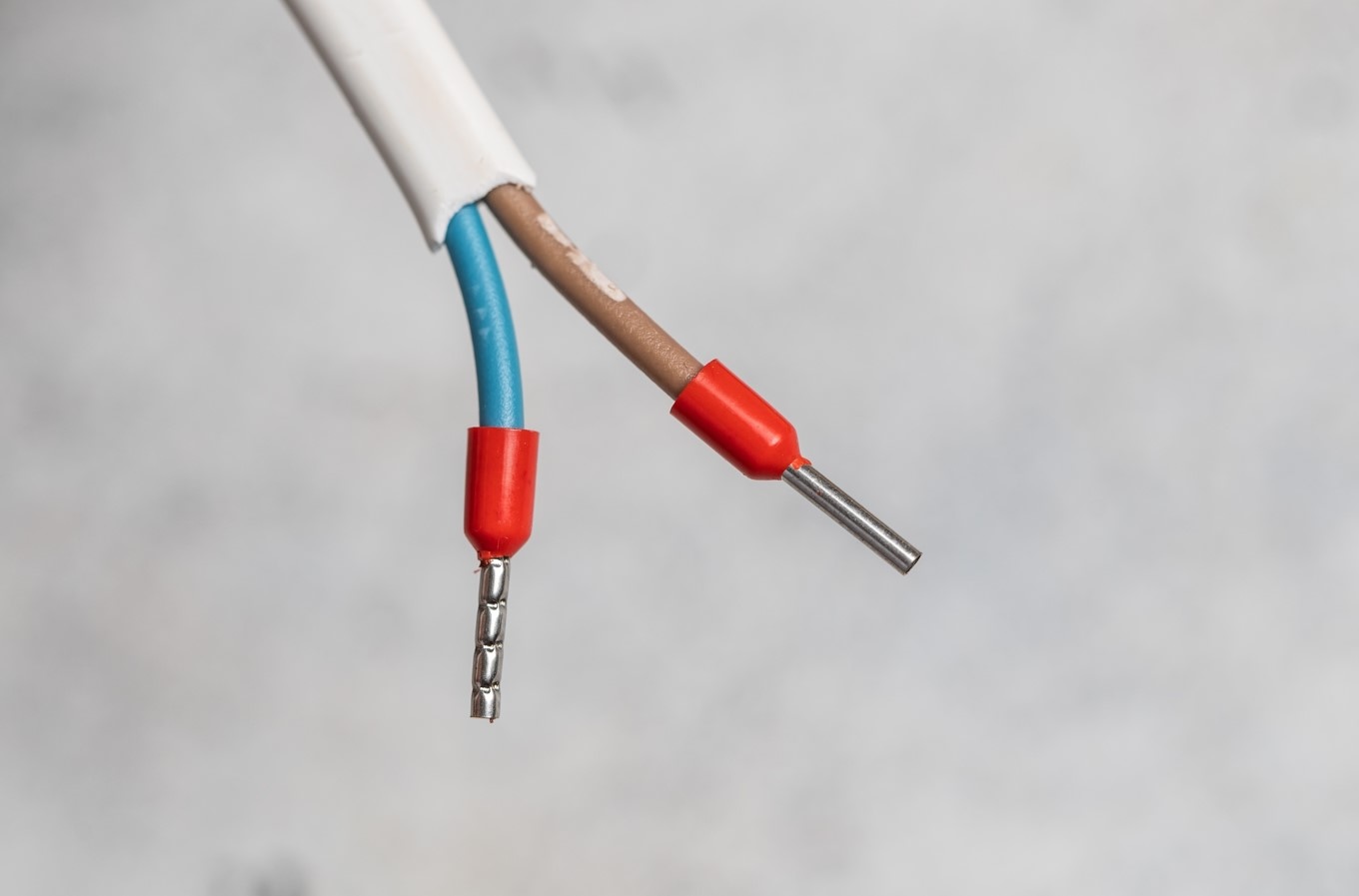

Crimping definition and common mistakes

The meaning of crimping can be summed up in one sentence: the process of tightly connecting wires to terminals to ensure a stable electrical connection.

Cable crimping: an in-depth analysis of crimping quality

In modern automotive wiring systems, crimp quality is critical to reliability and performance.

Why is industrial testing important in automotive component manufacturing?

The automotive industry is a dynamic sector and a hotbed of technological innovation. Component manufacturing is a key part of this industry, ensuring that vehicles meet the highest quality and safety standards.

EOL for on-board charger: How is the final check done?

Final inspection of onboard chargers is a key part of the manufacturing process. EOL (End of Line) inspections are designed to ensure products' high quality and reliability, thus avoiding the marketing of defective products.

The key role of EOL testing equipment in manufacturing quality assurance

EOL (End-of-Line) testing plays a key role in ensuring product quality at the end of the manufacturing process.

Measurement System Analysis (MSA): a solid basis for accurate measurements

Data measurement plays a key role in managing and optimising manufacturing processes. Let's see what you need to know about it!

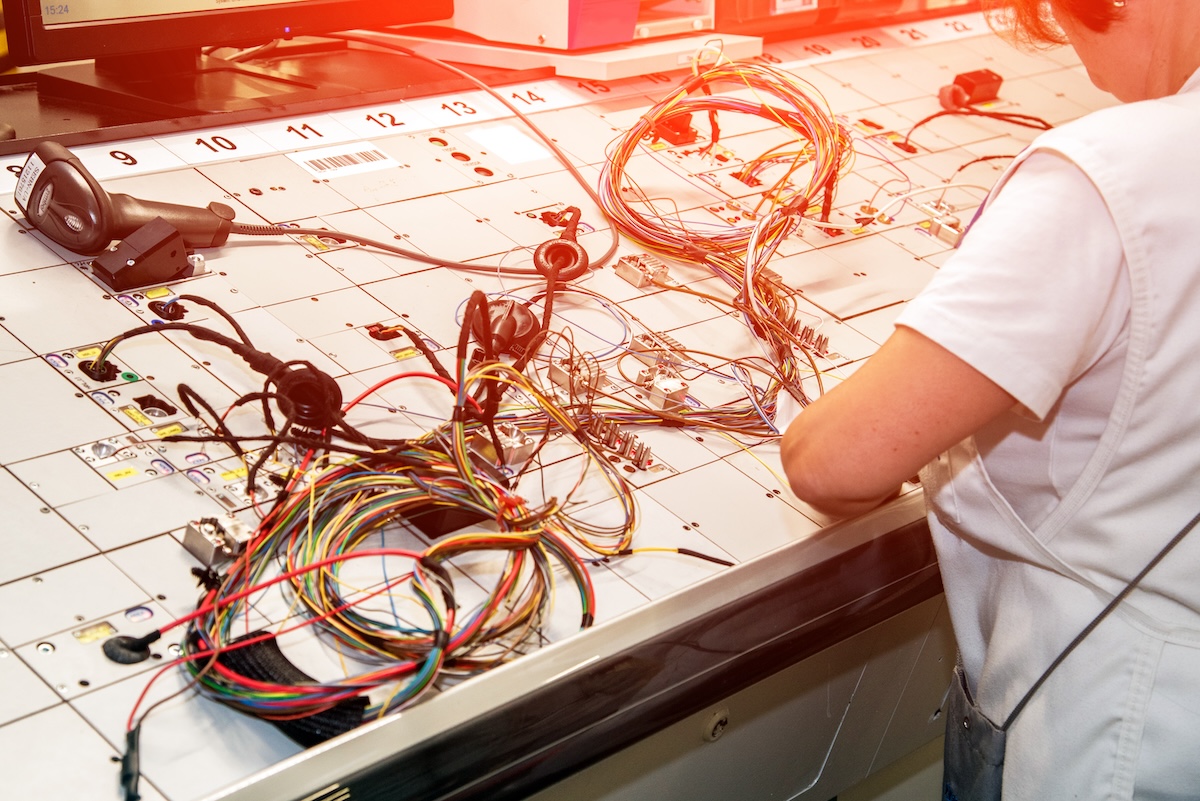

Importance of wire harness design software in modern industry

In modern industry, the design and manufacturing of cable harnesses are of paramount importance. Here, we have compiled the key aspects of wire harness design software!

MSA: Measurement System Analysis - The key to validating measurement systems

To ensure that manufacturers produce high-quality, reliable, and safe products, the application of effective measurement and testing procedures is essential.

Product validation in the automotive industry: the key to safety and quality

In this blog post, we delve into the topic of product validation and showcase how ProDSP assists in developing validation testing solutions!

Electrical equipment review: comprehensive testing from manufacturing to periodic checks

Faulty devices can lead to electric shocks or even fires, endangering lives and property. Therefore, electrical equipment review is essential.

Production line tester design and manufacturing: complex solutions for quality

Amikor az autóipar, a technológia fejlődése és az igények finomhangolása találkozik, ott a gyártósori teszterek tervezése és gyártása kerül a reflektorfénybe. Nem elég, hogy a modern világ rohamtempóban halad előre, a folyamatos innováció szellemében az autóiparban használt komponensek minőségének ellenőrzése is egyre nagyobb kihívást jelent. Mit kell tudni a gyártósori teszterek tervezéséről és miért a ProDSP a legjobb partner ebben?

Cable harrness production: the basis for future technologies

Cable harness production is more than just one process among many, this process breathes life into electronic devices by connecting the necessary components to function as efficiently as possible. The production of cable harnesses requires great diligence and attention, often needing to meet unique demands. What do you need to know about the cable harness production process? We've summarized it in this blog post!

Test sequence: the key to the testing process

Throughout the industrial revolutions, human efforts and production techniques have undergone radical transformations. The latest chapter in these processes is dominated by digitalization, where verification and validation mechanisms play a crucial role. The evolution of manufacturing processes continuously shapes the quality and reliability of products, which directly affects the market positions and reputations of companies. Testing is fundamental, and within it, the test sequence provides a framework for the procedure.

Design validation testing: when design becomes reality

In the dynamic world of design and manufacturing, Design Validation (DV) and Product Validation (PV) methods are crucial. These testing strategies are not only technical processes but also guarantees of quality and reliability. Design validation testing play a significant role across various sectors, including the automotive industry. Let’s explore what this concept entails!

All rights reserved. ProDSP Technologies Zrt. 2022 ©

Website built by Barna Design