Blog

Test Time Optimization in NI TestStand Sequences

The National Instruments TestStand environment is a powerful and flexible test automation tool widely used in industrial applications. It offers a variety of features to support implementation and debugging processes.

How to Write Effective Test Specifications – A Guide to Designing Industrial Test Systems

A well-written test specification document package not only steers customer communication into the right direction during quotation preparation, but also helps reveal technical risks, approach the technical content in the best possible way, and thus price a solution with the best price/performance ratio.

Measurement software: a background to industrial measurement

Measurement software enables manufacturers to collect and analyse data efficiently, bringing intelligence and precision to industrial process management.

NI Measurement software training at ProDSP

Measurement software training is a key driver of today's rapid technological advances and innovation.

Checking the reliability of crimped connections using a tension gauge

In modern automotive systems, the quality of the connection between wires and crimped contacts is critical.

Validation of Product Line Tester Measurement Systems

Several methods have been used in the industry, and we present here the statistical validation methods.

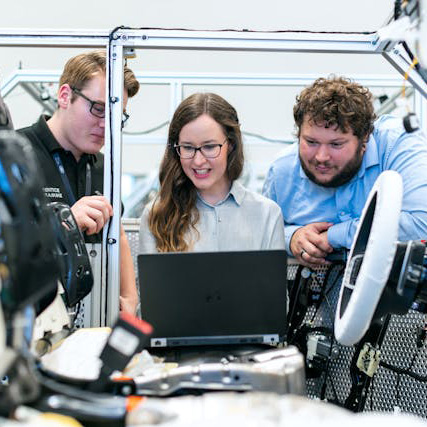

Creating well-being at work

As the world has developed and welfare societies have emerged, attitudes to work have changed.

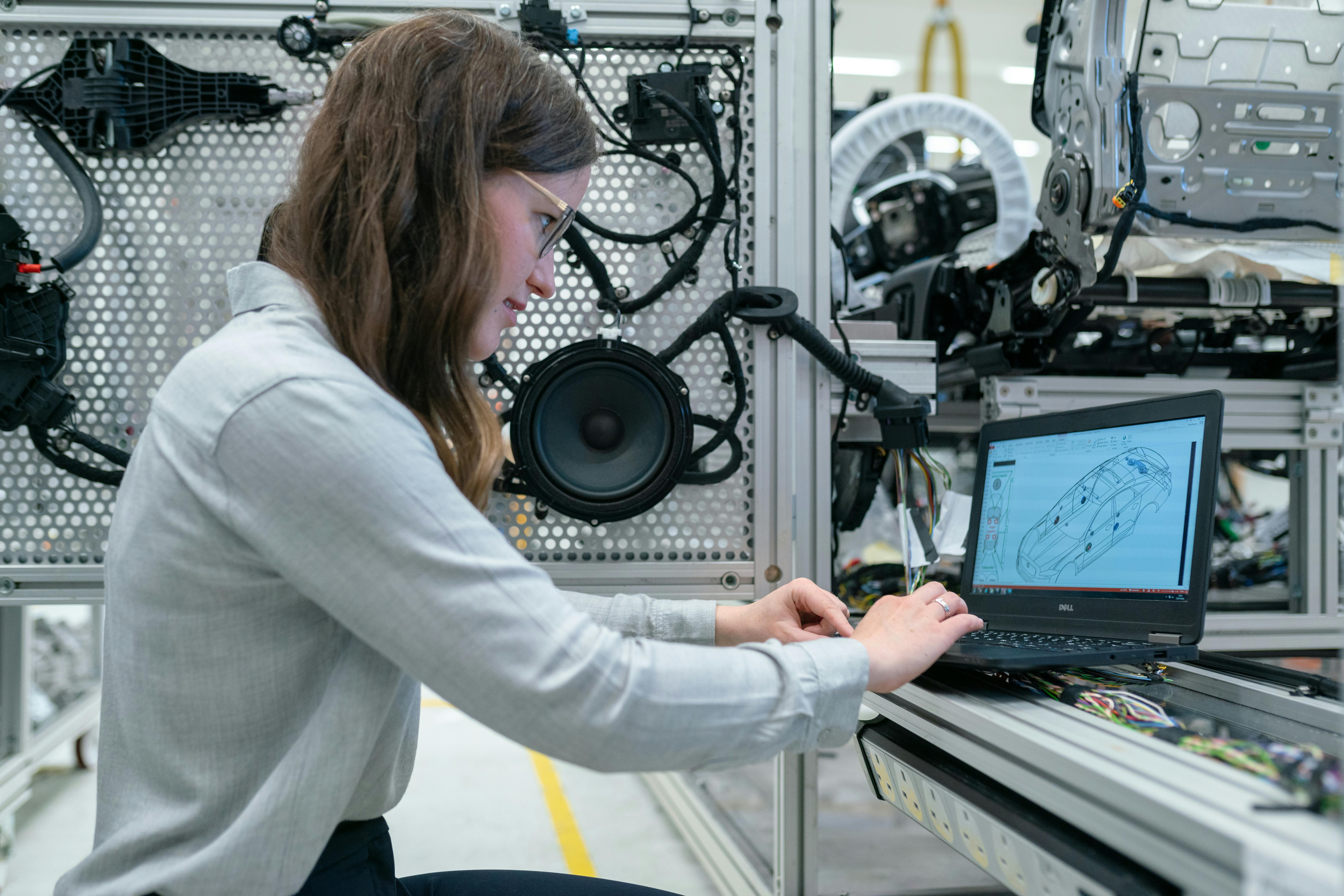

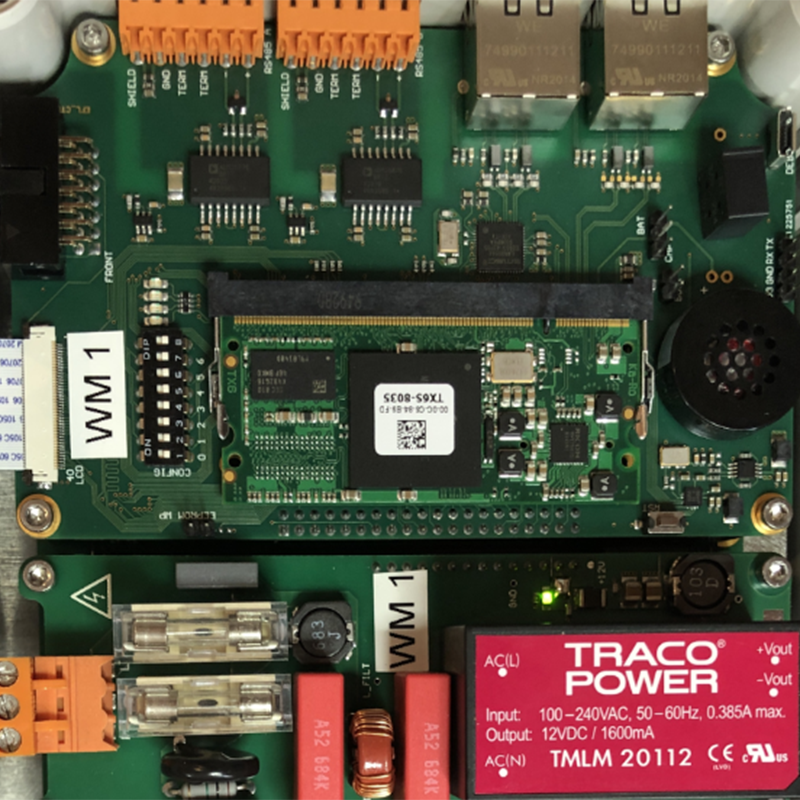

Hardware design at ProDSP

Custom hardware and software development tasks mark the 15-year history of ProDSP all the way.

Ismerkedés a Toradex modulokkal - egy izgalmas fejlesztés, számtalan előnnyel

2021 tavaszán egyik ügyfelünk azzal keresett meg minket, hogy készítsünk egy olyan platformot, ami alkalmas egy infrakamerás alkalmazás kifejlesztésére.

Efficient embedding of Single Board Computer in custom hardware

Developers today often face customer specifications setting stringent requirements concerning the devices to develop. Such requirements may be multimedia capabilities, complex mad-device connectivity, real time management of file systems, larger volumes of data and databases and connection to various encrypted networks.

Az autóipari tesztrendszerek aktuális kérdéseiről tanácskoztak a ProDSP szakmai napján

Az autóipari tesztrendszerek aktuális kérdéseiről tartott konferenciát a ProDSP Technologies Zrt. Budapesten, április 25-én.

Preliminary specifications, or how to find out what the customer needs?

Assessment of requirements is an element of paramount importance in implementing customer projects to the customer’s satisfaction. In the short blog post below, we introduce the key elements of this process from preliminary assessment through planning documentation and the system plan to determining responsibilities and conditions. Let’s see how the process starts!

Methods of electrical design in industrial testing (EPLAN)

Many people first encounter the term ‘current flow diagram’ when studying for an engineering degree. At that stage, they have no idea how important that knowledge will be later when they work on real-life industrial projects. The designer software market is full of excellent products. The software of choice of the electrical designer team of ProDSP is EPLAN Electric P8. This system has a comprehensive and constantly updated database. Hence, it is suitable for quick and precise designing. The macro database-driven customization of pages also gives an excellent opportunity to accelerate the design process.

Production line testing, a concealed key phase of automotive production

Be it conventional fossil fuel driven vehicles or the latest developments of e-mobility, automotive electronics is one of the most important elements of modern automobile production. The impeccability of the finished product largely depends on professional production line testing, a process where the test systems are the key elements. ProDSP has a decade of experience in the manufacturing and development of these test systems.

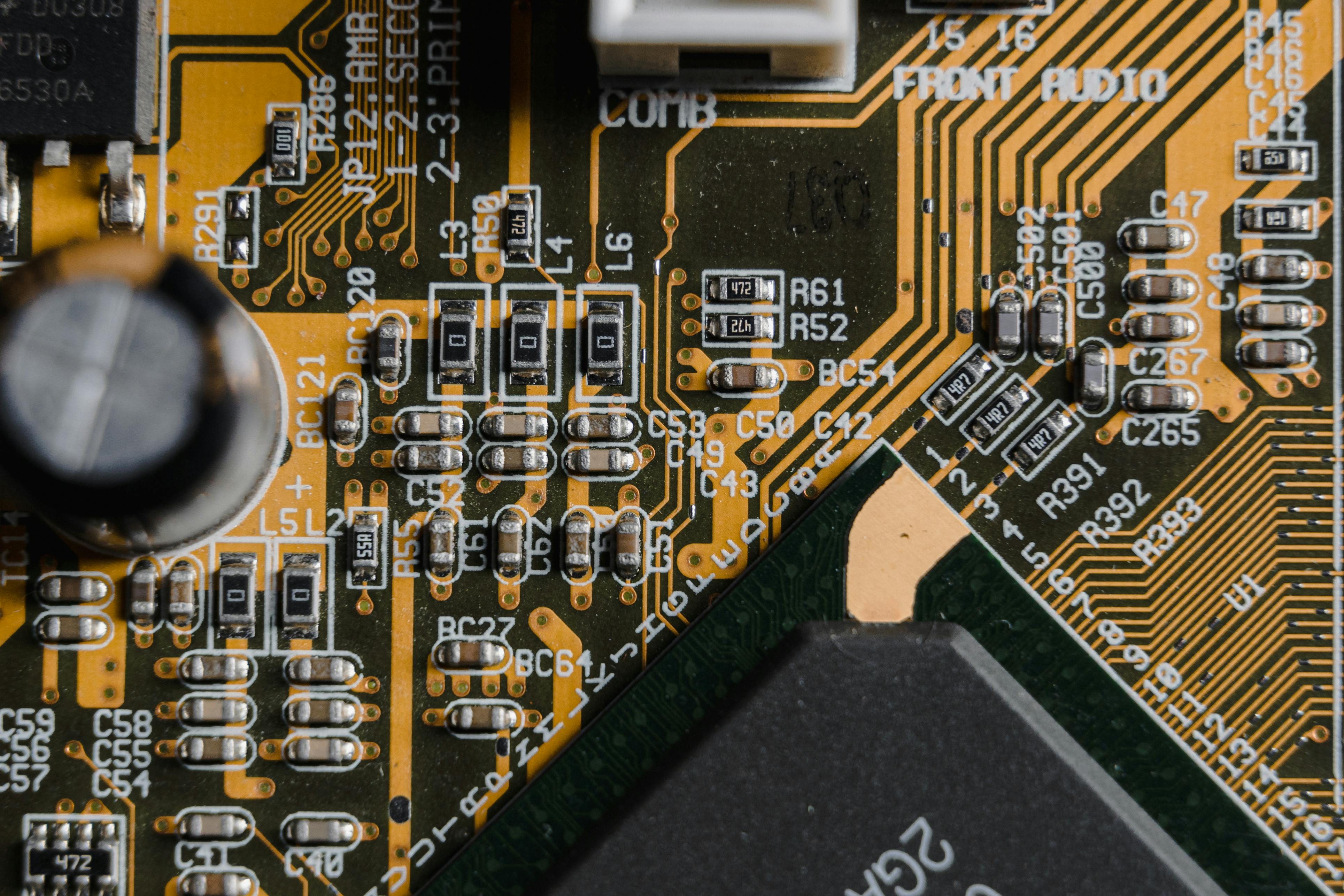

Production organisation information for the manufacture of printed circuit boards (PCBs)

During our work, we are often tasked by our partners with assignments related to the production and mounting of printed circuit boards. In our next post, we wish to offer them help with some practical guidelines that would make common work more efficient and faster.

Simple or complex end-of-line tester?

End-of-line testers are widely known in the industry as equipment that among others house instruments, mounting plates, electric devices and control elements. If only these arguments are listed of the end-of-line testers, we might as well say that “an end-of-line tester is none other than a control cabinet or a rack cabinet”. Reality is, of course, more complicated. From the machinery perspective, we distinguish simple and complex end-of-line testers, but it is important to know why the former or the latter is selected in a particular industrial project.

Is a software hardware?

Anyone setting out to be an electrical engineer, will learn at one point what hardware and software are. Basically, one doesn’t even have to be an electrical engineer for this, most people are aware what these words mean.

Trainee programme

Would you like to work in a live industrial project whole still at university? Then ProDSP’s trainee programme is just the thing for you!

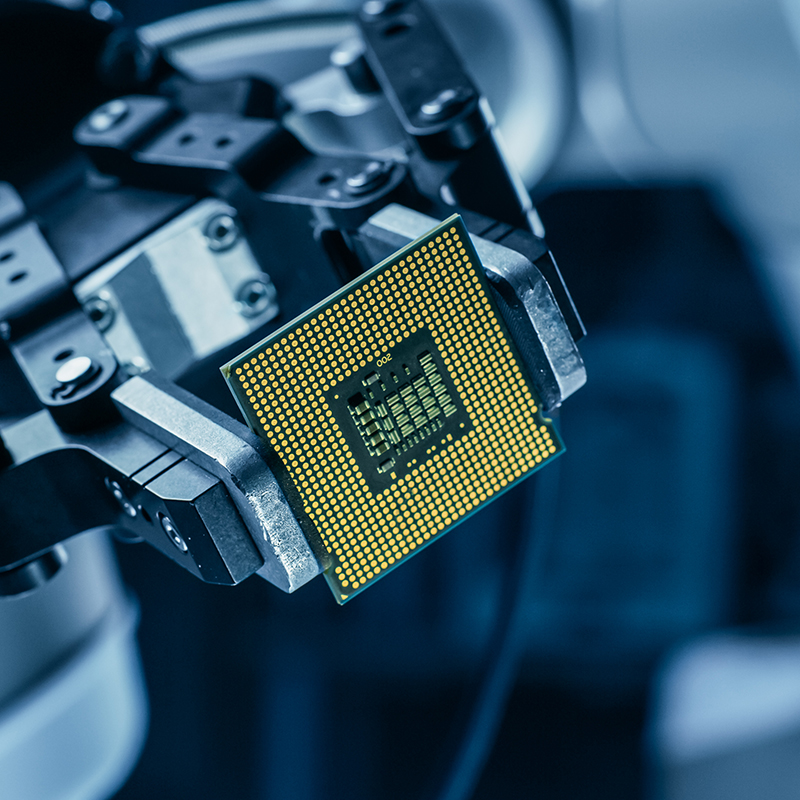

Chip shortage is survivable!

Efficient responses to the semiconductor supply crisis from the supplier side.

All rights reserved. ProDSP Technologies Zrt. 2022 ©

Website built by Barna Design