In modern industry, the design and manufacturing of cable harnesses are of paramount importance. The reliable operation of increasingly complex electronic systems, vehicles, and equipment necessitates the use of precisely designed and manufactured cable harnesses. During manufacturing, wire harness design software ensures that harnesses are appropriately designed and of high quality. Here, we have compiled the key aspects of wire harness design software!

Cable harnesses function as the nervous system of industrial products, ensuring the flow of electrical signals and power between components. Their reliability and performance directly influence the quality and lifespan of final products. It is no surprise that the automotive industry, aerospace manufacturing, defense industry, and many other sectors pay significant attention to the cable harness design process.

Designing cable harnesses is a complex engineering task that presents numerous challenges. Designers must consider electrical requirements, spatial constraints, environmental impacts, and manufacturability. Traditional manual design methods are time-consuming and prone to errors. With increasing market pressure, companies need more efficient solutions for cable harness design.

Cable harness design software has revolutionized the industry by allowing engineers to optimize the design process using digital tools. These software applications speed up the creation of cable designs, minimize potential errors, and support effective collaboration among teams. Advanced features like automated routing, component databases, and simulation tools significantly simplify the designers' work. Using wire harness design software, companies can save substantial time and costs while improving the quality and reliability of their final products.

Key features of wire harness design software

One of the critical functions of wire harness design software is schematic design and drawing creation. These programs enable users to create detailed and accurate drawings of the structure and layout of cable harnesses. Comprehensive component and wire databases facilitate the design process by allowing engineers to quickly find and select the necessary components for their projects.

The advanced routing and layout optimization capabilities of the software ensure that cable harnesses are designed in the most efficient way possible. Automated documentation generation simplifies the creation of manufacturing documents, as the software can produce detailed bills of materials, connection diagrams, and other required documents.

Integration with other design systems, such as CAD and PLM software, allows for seamless data exchange and collaboration among different engineering teams, enhancing the efficiency and accuracy of the design process.

Benefits of using wire harness design software

The use of cable harness design software offers numerous advantages for engineers and manufacturers. One of the most significant benefits is the drastic reduction in the time required for design. With automated tools and intelligent algorithms, cable harness design becomes much faster and more efficient.

The software also significantly reduces the potential for errors, as it automatically checks designs and flags any issues. This contributes greatly to improving the quality of the manufactured cable harnesses, as errors can be identified and corrected during the design phase.

Cable harness design software enables effective teamwork and communication between different departments. Thanks to cloud-based solutions, team members can access designs from anywhere at any time and collaborate in real-time.

3D visualization tools allow designers to easily understand the structure of complex cable harnesses, while providing impressive and convincing presentations for clients. Parametric design enables quick modifications, allowing for flexible adaptation to changing customer needs.

In the event of changes in customer requirements, the software makes it easy to manage modifications and updates. Designs can be quickly transformed, and new versions can be seamlessly shared with team members.

Lastly, the software optimizes material usage and costs. Through intelligent routing and component databases, the software helps minimize the amount of materials used, thereby reducing manufacturing costs.

The introduction of cable harness design software has a significant impact on the performance and competitiveness of manufacturing companies. By automating and optimizing design processes, productivity can be increased, while turnaround times are significantly reduced.

These factors collectively contribute to strengthening market positions and gaining a competitive edge. Companies that use cable harness design software can manufacture complex cables more efficiently, quickly, and with higher quality, standing out from the competition.

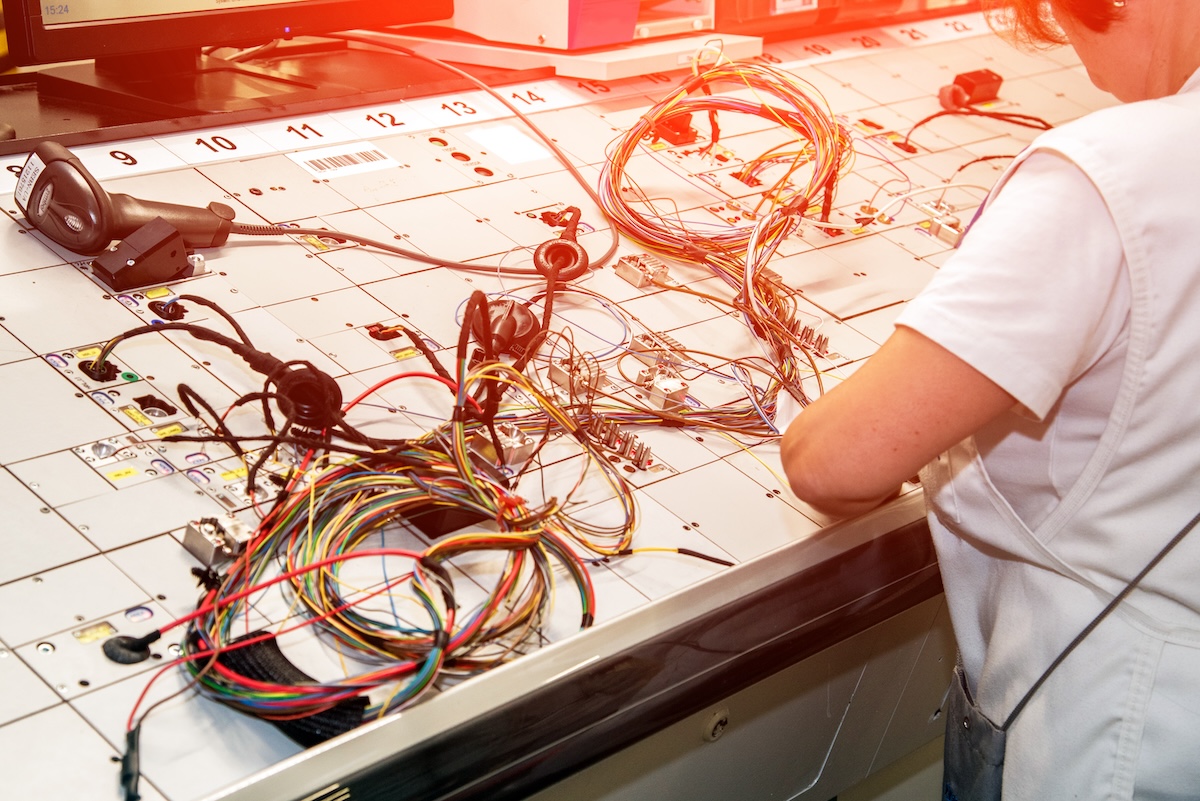

Using Cable Harness Design Software at ProDSP

At ProDSP, the use of cable harness design software plays a crucial role in our design and manufacturing processes. Clients often come to us with initial concepts or documentation, but they may lack the in-depth technical knowledge needed for cable manufacturing.

This is where we step in. Our engineers combine the information provided by clients with our extensive expertise, accumulated over many years, using the software to develop the most optimal solutions. This blend of client input and our technical know-how allows us to add significant value for our clients.

During the design phase, we incorporate our acquired knowledge and experience into the drawings. The software enables us to create precise manufacturing drawings that include both client-provided data and the technical parameters we determine.

These detailed documents serve as the foundation for both our internal manufacturing unit and our subcontractors, ensuring clear guidance throughout the production process. We rely on these drawings during the inspection of the produced cables to guarantee correct dimensions and pin assignments.

The cable harness design software allows us to effectively apply our engineering expertise, resulting in high-quality, custom-tailored cable harnesses that meet our clients' needs.

More details about our custom cable harness production services can be found on our website!