The basics of safe manufacturing

The number of industrial machines in Hungary ranges from tens of thousands to hundreds of thousands, depending on the exact category of machines counted. Every day, hundreds of thousands of people come into direct or indirect contact with this machinery and are at risk if it breaks down or is used incorrectly. The same figure rises to several million when extended to the European Economic Area. It is clear, therefore, that proper regulation is essential to the manufacture and operation of equipment.

For the Member States of the European Union, the construction and operation of machinery is governed by regulations and directives. What is written in regulations is uniformly binding for all EU Member States. Directives only set out mandatory objectives which each country is responsible for achieving through appropriate regulation.

The most important directives concerning machinery and industrial equipment are:

- 2006/42/EC Safety of machinery

- 2014/35/EU Low Voltage Equipment

The Machinery Safety Directive is aimed at manufacturers of machinery and safety components. It covers newly installed machinery, components placed on the market independently and machinery and equipment imported from outside the European Union. The main objectives of the Directive are a safe design of machinery, technical documentation, availability of instructions for use, and issuing of a declaration of conformity.

Standards are technical documents, drawn up and/or approved by recognised organisations, which set out requirements for processes or their results and define methods that can be reused and provide an optimum solution in the field they cover. Although the use of standards is voluntary, they have the important advantage that they do not require the need to prove the adequacy of a solution by tests or calculations.

The standards set requirements for the design of machinery at four levels: A, B1, B2, and C. Type A standards set general safety principles. Standards of type B1 deal with conditions, such as ISO 13857:2020 - Prevention of access to hazardous areas by upper and lower limbs. Type B2 standards deal with safety devices, such as ISO 14120:2016 - Protective enclosures. Type C standards focus specifically on a particular type of equipment, e.g. EN 619:2022 - Conveyor systems.

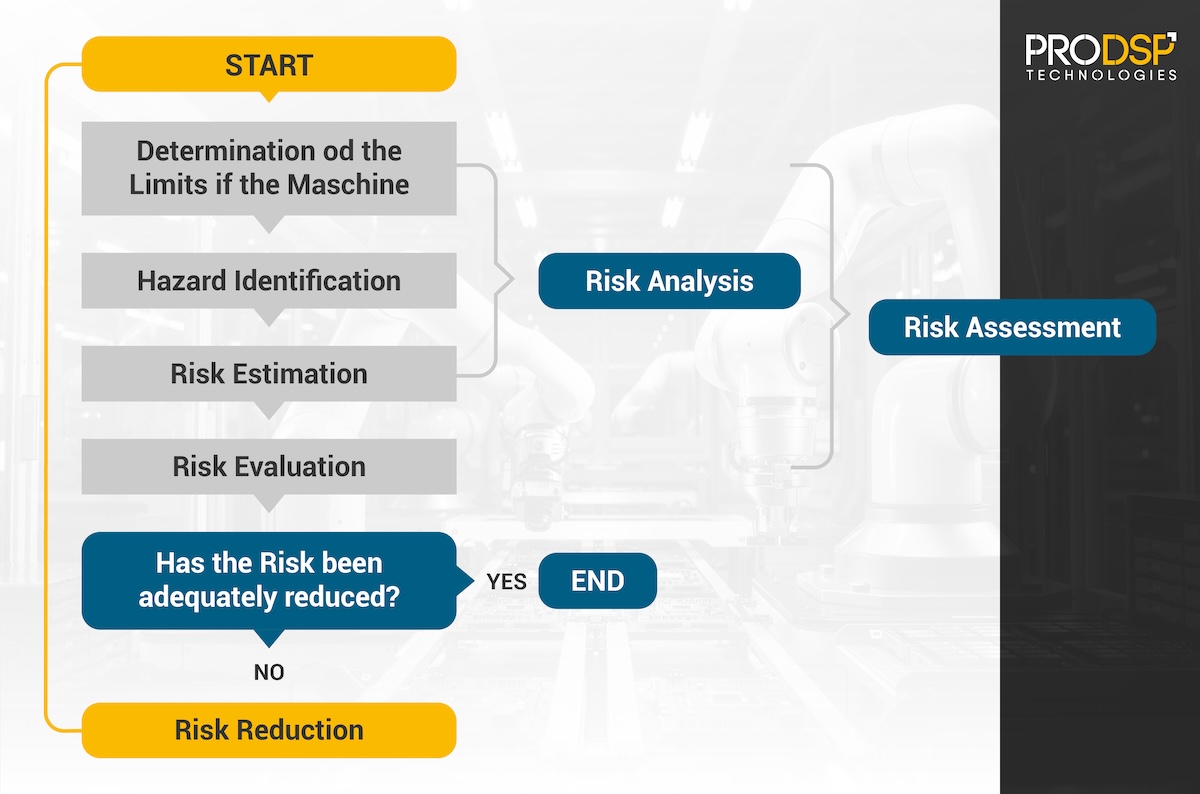

The focus of this article is ISO 12100:2010 - Safety of machinery - General principles for design. Risk assessment and risk reduction, a Type A standard for machinery and industrial equipment. It provides a common methodology for machine manufacturers and operators to standardise the quality of individual and small series machines. According to the standard, risk assessment is mandatory in the major life cycles of the equipment (design, installation, relocation), but can also be used in any other situation as a safety review.

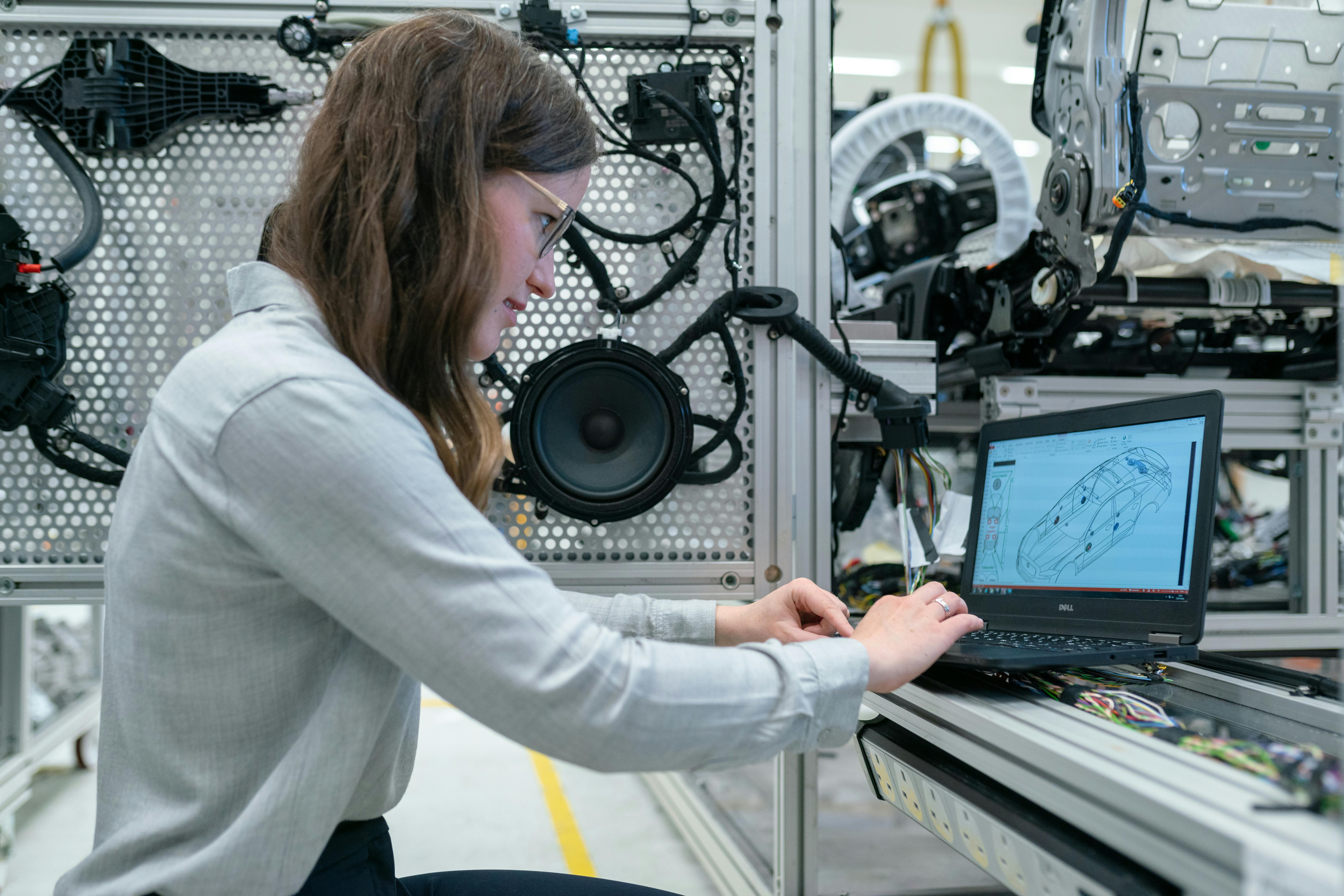

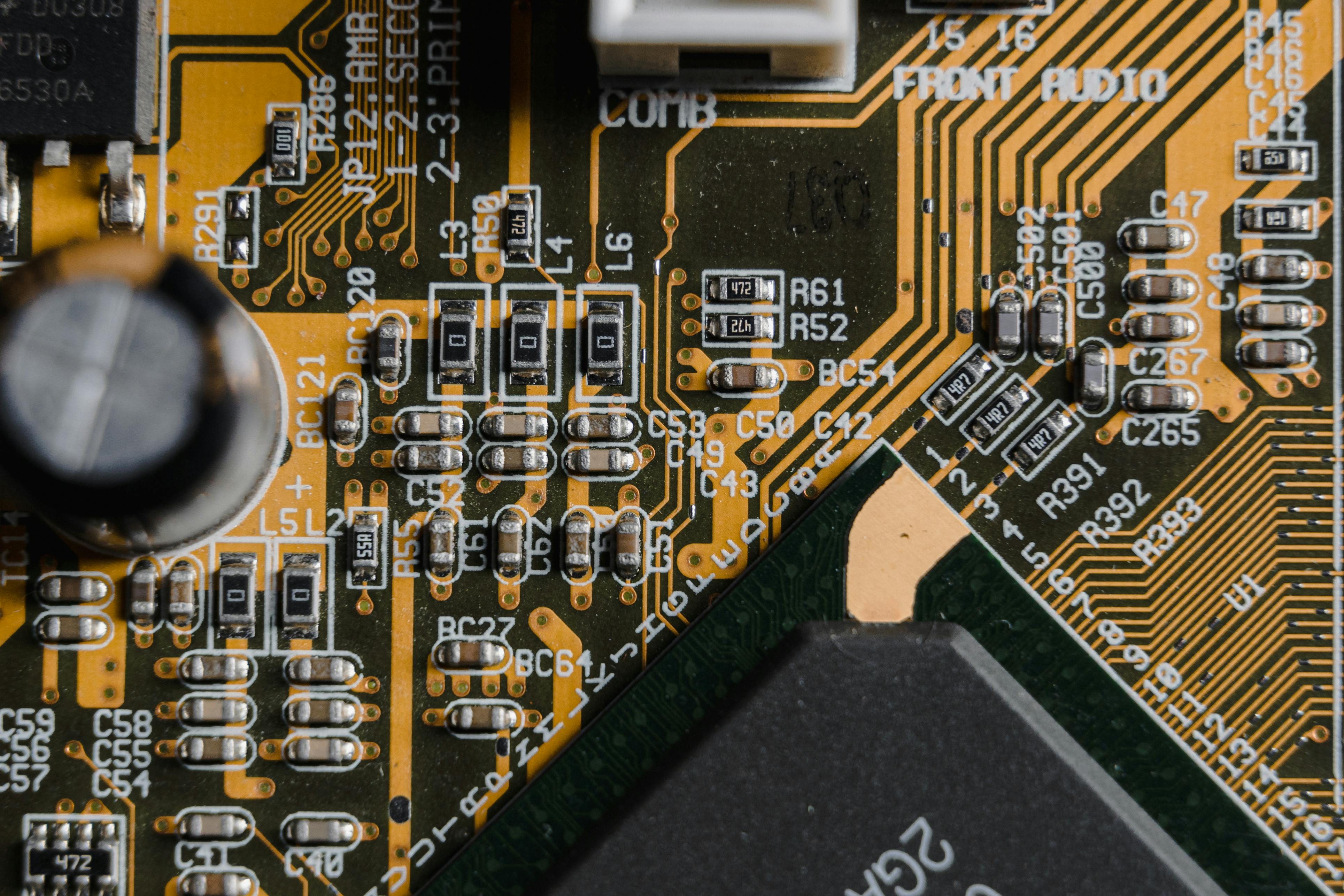

To illustrate the usefulness of risk assessment, consider as an example a function tester for printed wiring plates, designed to check specific products in an automated way with minimal operator intervention. Such a machine contains several potential hazards for the operators. Based on ISO 12100, the potential hazards can be eliminated as follows:

First, the temporal, spatial and other (e.g. use) boundaries of the equipment must be defined, which will help to delimit the set of potential hazards. In the case of the example machine, the physical boundaries are the edges of the machine geometry and the pneumatic and electrical supply lines. The temporal boundaries are the duration of the machine's life cycle. Among the other boundaries, it is necessary to consider, for example, how persons (operators, maintenance staff) interact with the machine.

Once the boundaries have been established, the next step is to identify the hazards.

In the case of the example machine, these could be pneumatic movements, electrically active touch parts, and several other hazards. One of the most effective forms of hazard identification is brainstorming.

The next step in risk analysis is to estimate the extent of the risk and evaluate the result. There are several methods for quantification from which to choose, or, with sufficient experience, you can develop your own method.

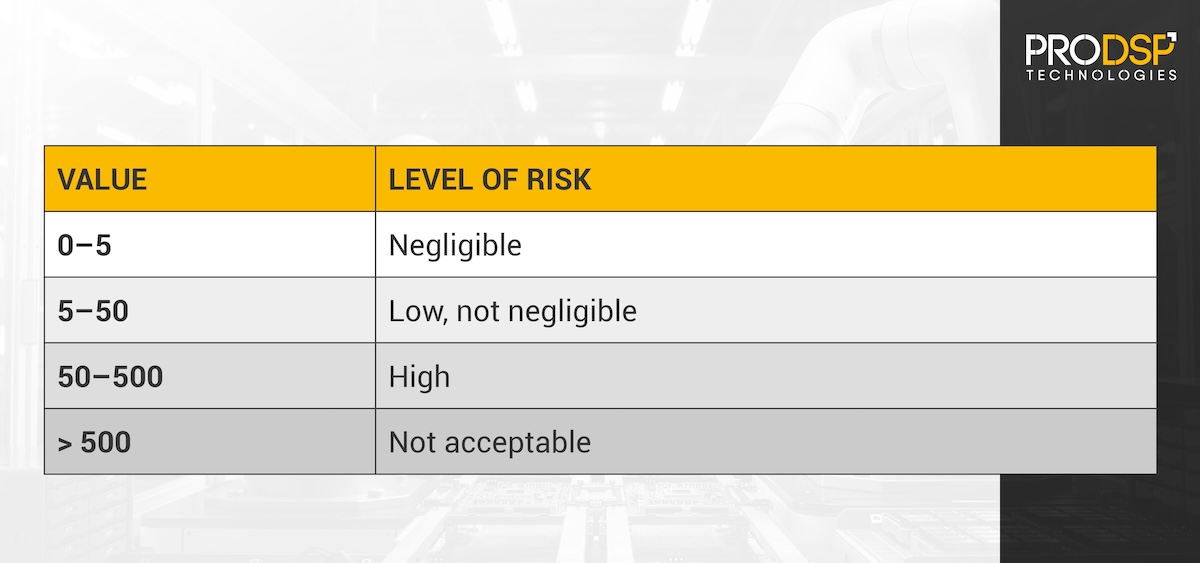

In ProDSP, the determination of the level of risk typically depends on the following parameters of the identified hazard:

- Probability of hazard occurrence (O)

- Frequency of exposure (E)

- Severity of worst-case injury (S)

- Number of people exposed to the hazard (P)

Weighting and summing these aspects on a scale, the risks are placed in one of the following bands:

When looking at the pneumatic parts of the example tester, the probability of a limb being pinched without protective measures is quite high, corresponding to a value of 8 on the scale used by the ProDSP. The exposure frequency in automatic mode is at a minimum daily level of 2.5. The worst injury could be a minor bone fracture, corresponding to a value of 2. Number of exposed people: anyone who may come near the machine. In a large production hall, this is typically more than eight people, which is worth 4 points. The score for this risk is 160. The identification of the other risks for the machine is done analogously

The next step is to evaluate the results. The value of 160 in the example above corresponds to a high-risk level, so it is essential to apply risk mitigation measures. According to ISO 12100, risks can be managed in three steps.

Firstly, built-in safety measures are applied, whereby the designer uses methods and materials that will prevent the hazard themselves. This may be to reduce the force of the working cylinder so that it cannot cause serious injury, provided that the force exerted by the cylinder is still sufficient to perform the task.

Where the methods of the first step are not applicable, additional design measures are needed to provide additional protection. For example, dangerous work rollers can be enclosed by fixed and openable covers by ISO 14120.

The third step applies to risks where their extent is not negligible, and the risk cannot be further reduced. If there is no way to reduce the force of the dangerous working rollers to an appropriate level or to isolate the working roller from the operators, the residual risks must be addressed by additional measures. Such measures include, for example, marking moving parts with yellow pictograms warning of the danger by IEC 60417-SN. Furthermore, instructions on the hazards must be included in the operating instructions for the equipment and, where appropriate, the operating personnel must be trained and provided with suitable protective clothing.

It is important that the sequence of application of the three methods is not interchangeable and that they are used in complementary order to provide maximum protection.

The next step in the risk assessment is to re-examine the machinery, supplemented by mitigation measures, considering that new risks may arise because of the measures taken. This iterative process should be continued until all risks are reduced to an acceptable level.

The above case study illustrates how standards provide effective and easy-to-use tools for machine designers and operators to build and operate safer machines. The correct application of standards is therefore a key element in ensuring that everyone gets home from work safe and sound.

Barnabás Illényi - Electrical Design Engineer