Hardware design at ProDSP

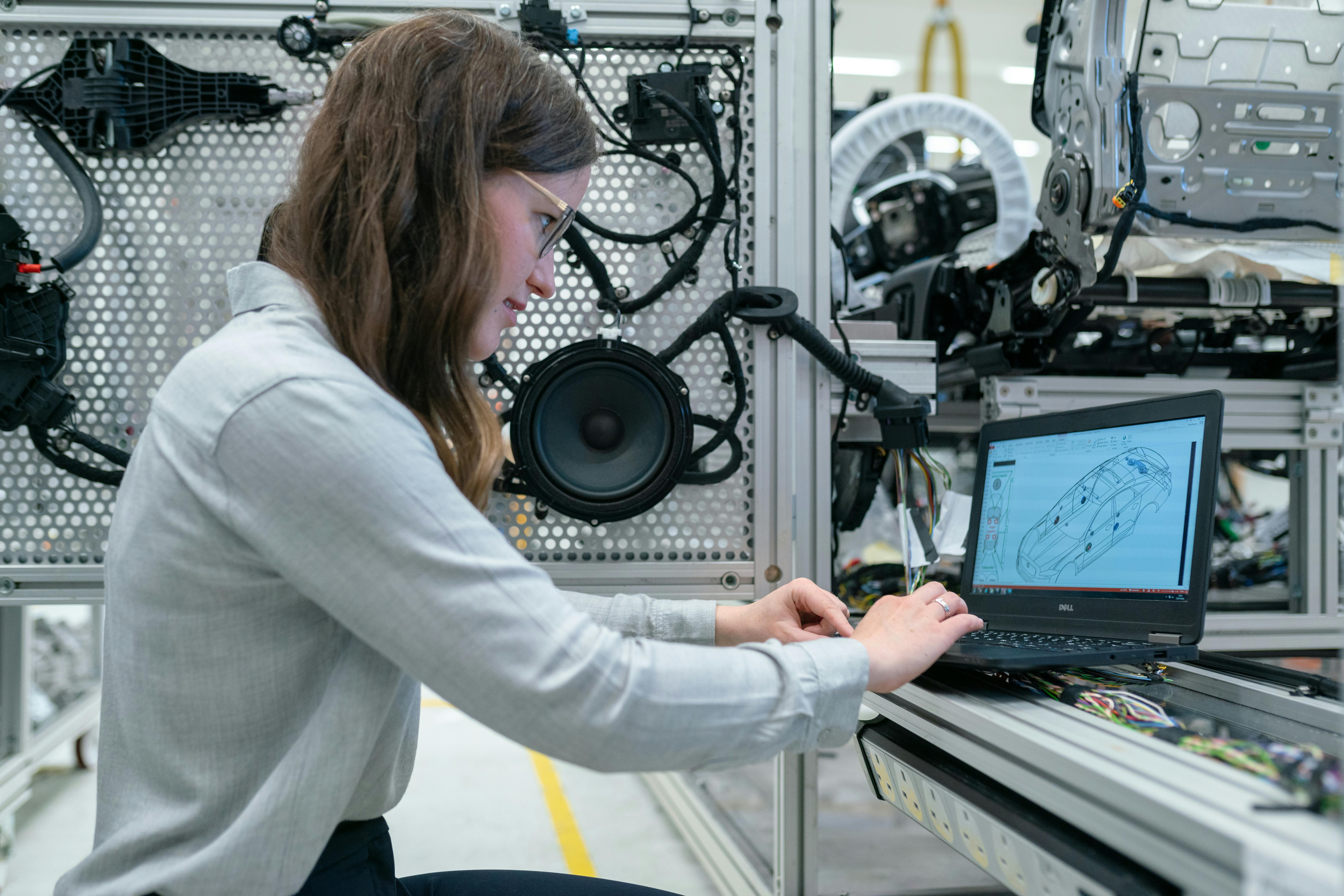

Custom hardware and software development tasks mark the 15-year history of ProDSP all the way. One of the main pillars of corporate knowledge base is the broad knowledge acquired during this period. This is no different in the time of inline test systems either, as custom made hardware are also used in end-of-line testers, provided this results in better and more economical technical solutions. Parallel to this, as an independent field, custom hardware design remains part of the company portfolio.

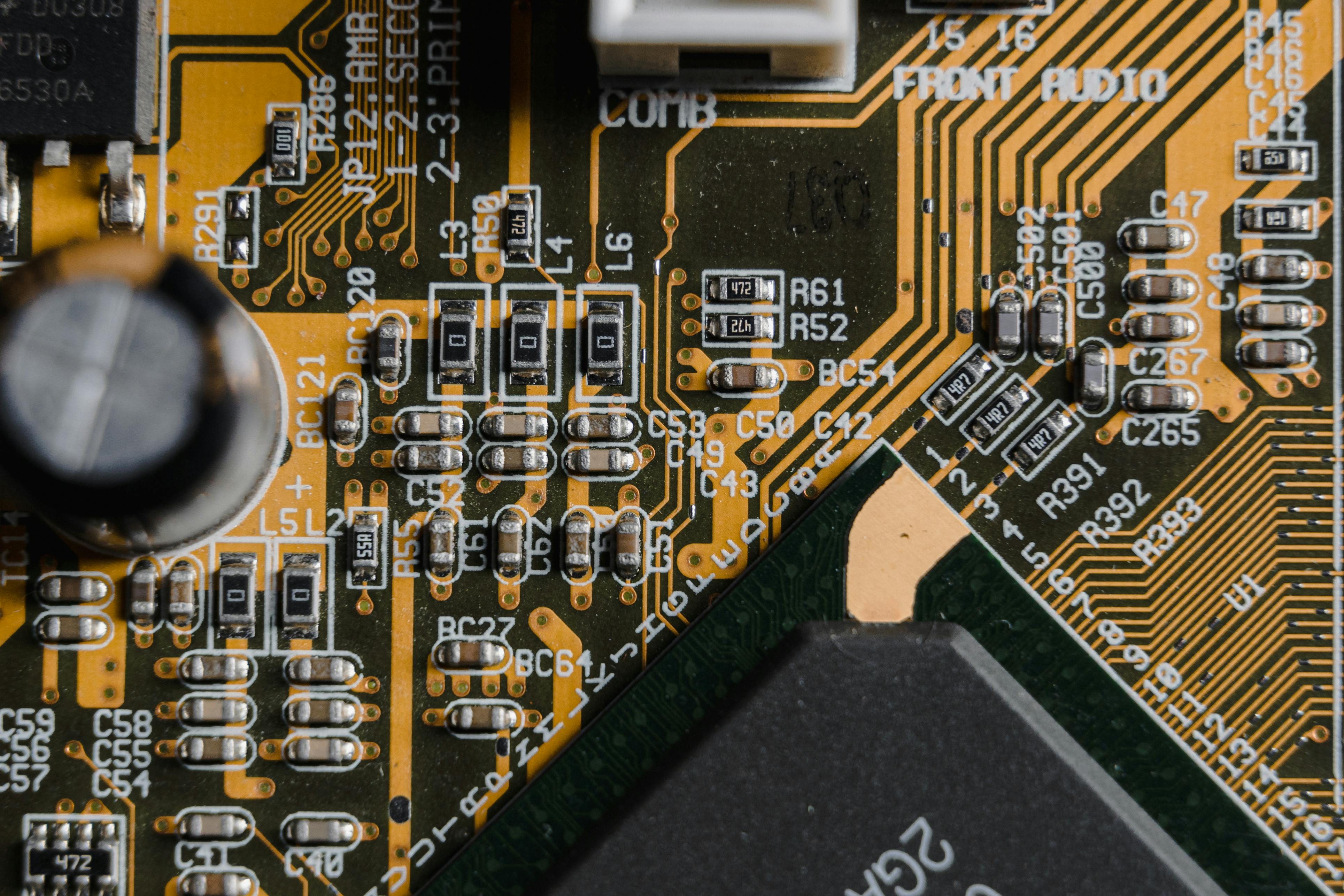

Hardware design encompasses a very broad range of professional activities. Indeed, if we wish to systemically categorise the works that belong here, defining the very criteria seems to be a difficult task. Custom hardware manufactured in small series or circuits of serial produced products? Extremely low power consumption connections or large cards for power electronics? Solutions adhering to industrial standards or a development environment that is intended for the desk of another engineering team? They all carry that proprietary perception and experience, based on which any customer inquiry can be met with the optimal solution.

This blogpost provides insight into the hardware design works undertaken by ProDSP, according to whether we have already worked in the topic in question. One group includes the projects where we are contacted for performing a task that resembles a previous job. Another group is when the inquiry topic is new for us, but relying on our basic professional expertise, we can be an understanding partner in elaborating the solution.

Recurring tasks

Jobs we are tasked with can often be matched to an area where we already have experience and good references.

- Works traceable to image processing are often about analysing the image of a camera, e.g. when examining the integrity of a workpiece, interpreting pictograms and detecting movements. The output may be some kind of measured value or a simple good-bad decision. Although the analysis is software based, our hardware, mechanic and installer team can perform the design and deployment of the corresponding instrumentation in-house.

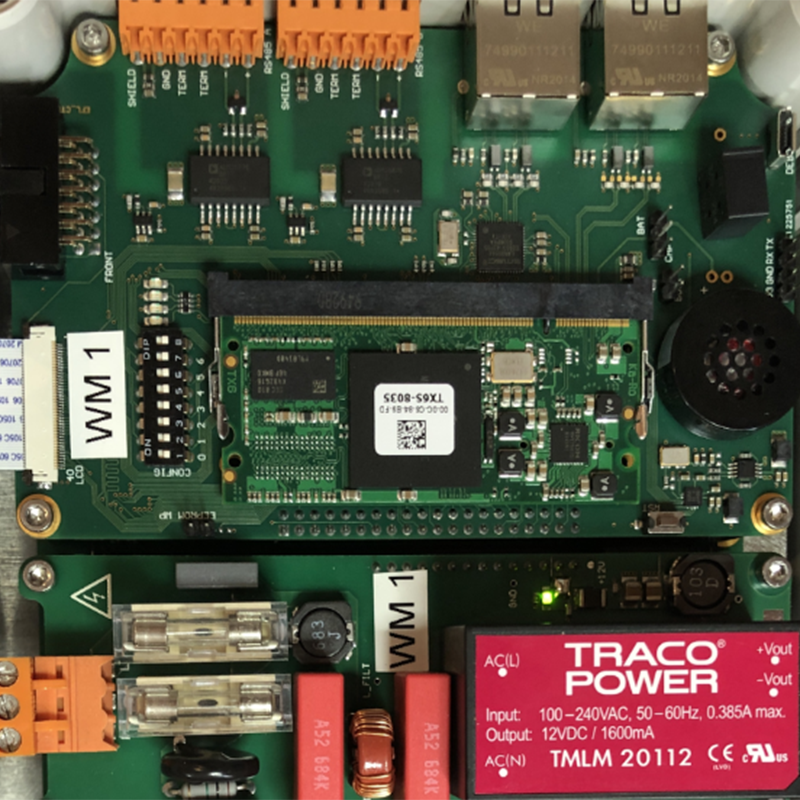

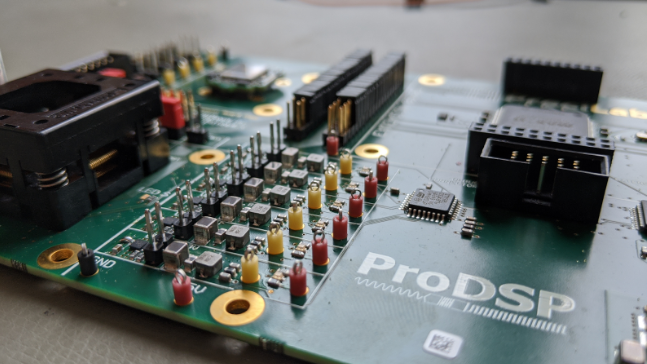

- Another recurring task is the integration of the various SBC, SOM modules on individual cards. For this, we design motherboards and carrier boards that extend the functionality of the base card according to the customer’s needs, providing the requested connections. For example, consider the use of the Toradex modules, which we have equipped with PoE (Power over Ethernet) extension, with an adapted camera module. We also use modules with iMX6 processor from Ka-Ro’s range, as well as Raspberry compute modules.

- It often happens that we are sought no measure non-electrical quantities. The main considerations for these tasks are the installation of the appropriate sensors and the selection of a platform suitable for collecting the data. Here, we can follow two philosophies: building a classical, microcontroller-based embedded system, or solve the metrological part from NI components, with the help of LabVIEW. In this field, we spent most time with the precision measurement of position and displacement, based on the aforementioned image processing method.

Unconventional challenges

The other group of our challenges are unconventional challenges, where the task is essentially interpreted together with the customer in the course of a longer period of cooperation.

- Here, we can consider research and development type work, where we are not serving a clear industrial requirement, but are working one step before that. We are able to dig deep in a particular topic, even to the level of fundamental science, then, seek a solution for developing the idea into a technical solution by brainstorming with the customer. One of the most important part of these works is the reconciliation of requirements and professional realities, finding the optimal compromise. In many cases, we are able to warn of the disadvantages of a particular solution, offering the optimal one instead. Aspects to consider may be safe operation, a realistic price or the security of producibility.

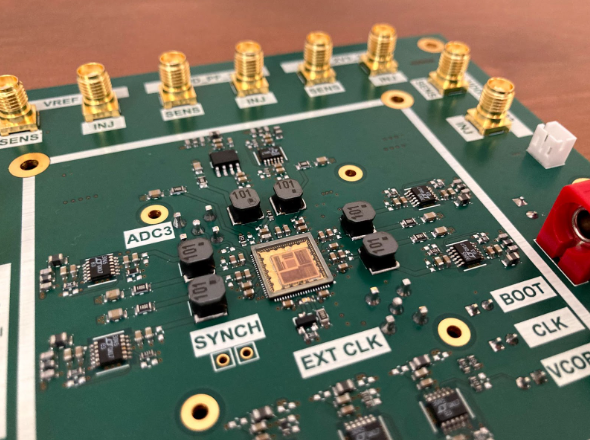

- We build custom test environments for ourselves or our customers, in which we use both factory instruments and custom designed boards. In such cases, the hardware and software teams of ProDSP closely cooperate, allowing design of our cards that help subsequent software development work. It is worth mentioning that we have elaborated a characterisation platform, in which we examine how the extra electric noise influences the images of a camera module.

As a summary, it can be established that we operate over a broad range of challenges related to hardware design. In fields known in depth, our experience contributes to efficient and rapid design, and we are also able to develop valuable cooperation in elaborating topics harder to grasp.

And as for our favourite of the above challenges? Our colleagues generally opine that they prefer to work in depth on projects where ProDSP’s professional teams can work jointly on a larger task, over a longer period of time, B be it a clear hardware-software cooperation or a broader service, in cooperation with mechanical engineering.

Author:

Tamás Szalma,

Senior Hardware Designer Electrical engineer