Simple or complex end-of-line tester?

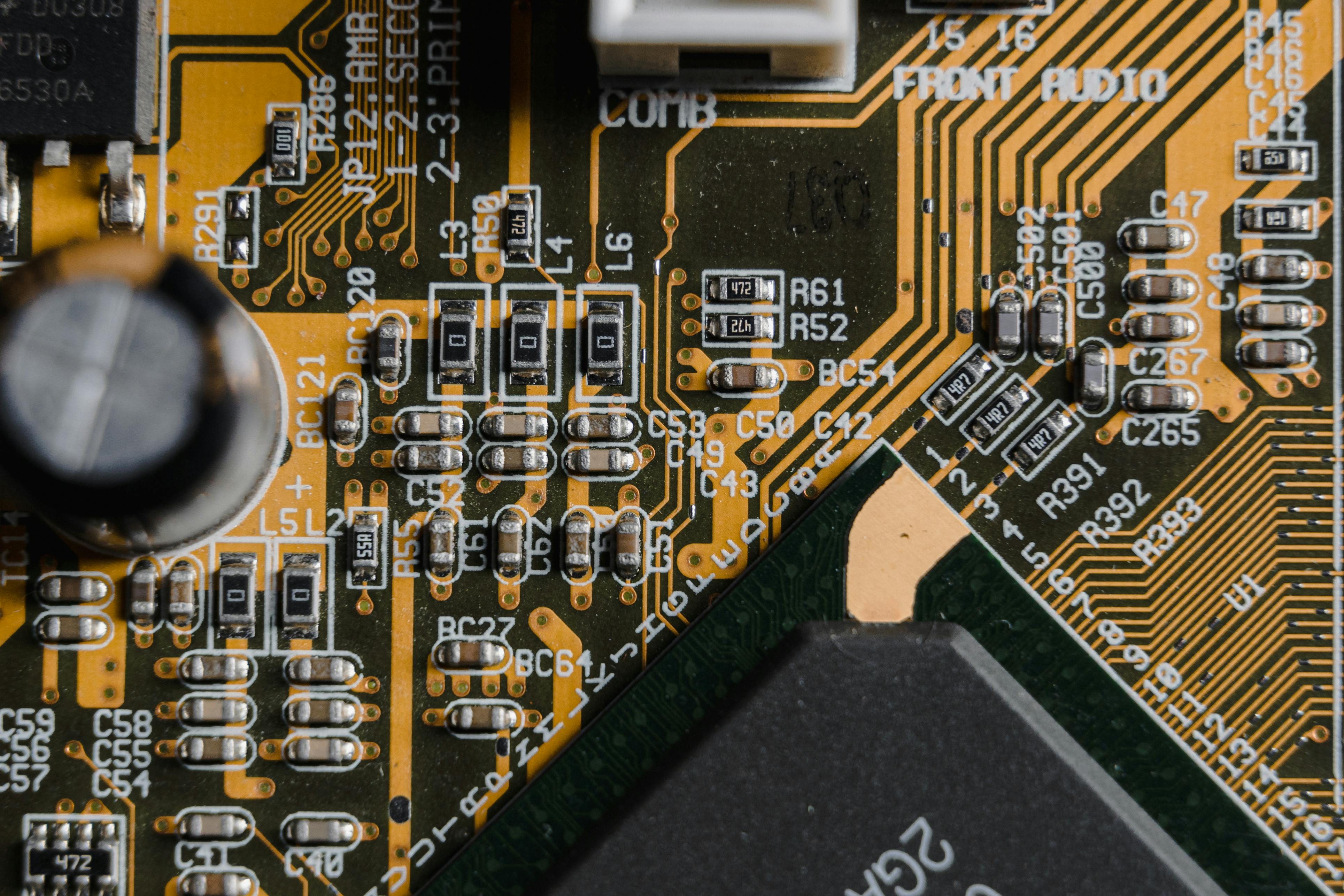

End-of-line testers are widely known in the industry as equipment that among others house instruments, mounting plates, electric devices and control elements. If only these arguments are listed of the end-of-line testers, we might as well say that “an end-of-line tester is none other than a control cabinet or a rack cabinet”. Reality is, of course, more complicated. From the machinery perspective, we distinguish simple and complex end-of-line testers, but it is important to know why the former or the latter is selected in a particular industrial project.

What is the “problem” with a simple end-of-line tester?

Simple end-of-line testers are usually built from commercially available elements. This means in practice that following purchase of the switch cabinet and the corresponding commercially available construction elements, the aforementioned instruments and other devices are simply installed in the equipment purchased. This, however, doesn’t always produce the desired results.

As diverse as the technological range of elements and accessories available for the cabinets may be, there can still be situations where no accessories are available for a certain instrument (e.g. an installation frame), or if available, it is either out of stock or may not even be compatible with the target system without having to modify it.

Modifications, however, may postpone already the not particularly short delivery deadlines, which is no interest of the supplier and the customer.

In what is an end-of-line tester manufactured by ProDSP different from the others?

The specialist engineers of our company have decades of developer experience, meaning that we can easily substitute commercially available components such as cabinets, installation frames, etc. with our proprietary items.

Therefore, if it is not possible to implement an end-of-line tester by the given deadline, or if custom solutions must be applied during the project to compile the entire system, we solve the problem by building from our proprietary elements.

In order to optimise the processes, for example, we have created an internal an a standard element inventory, with the help of which our machinist designers can design the end-of-line tester in question.

We stock several elements from this element inventory, in order to reduce lead times. We can thereby supply more competitive products, matching 100% of customer requirements with short delivery deadlines.

Thanks to this solution, the majority of the design work of the testers can be performed immediately, so the designers’ efforts can be concentrated on the components requiring custom solutions.

For simpler end-of-line tester-type production projects, the product specific parts may occasionally be provided by the customer, or if we prepare them, they are implemented as a separate design unit.

What makes an end-of-line tester “complex”?

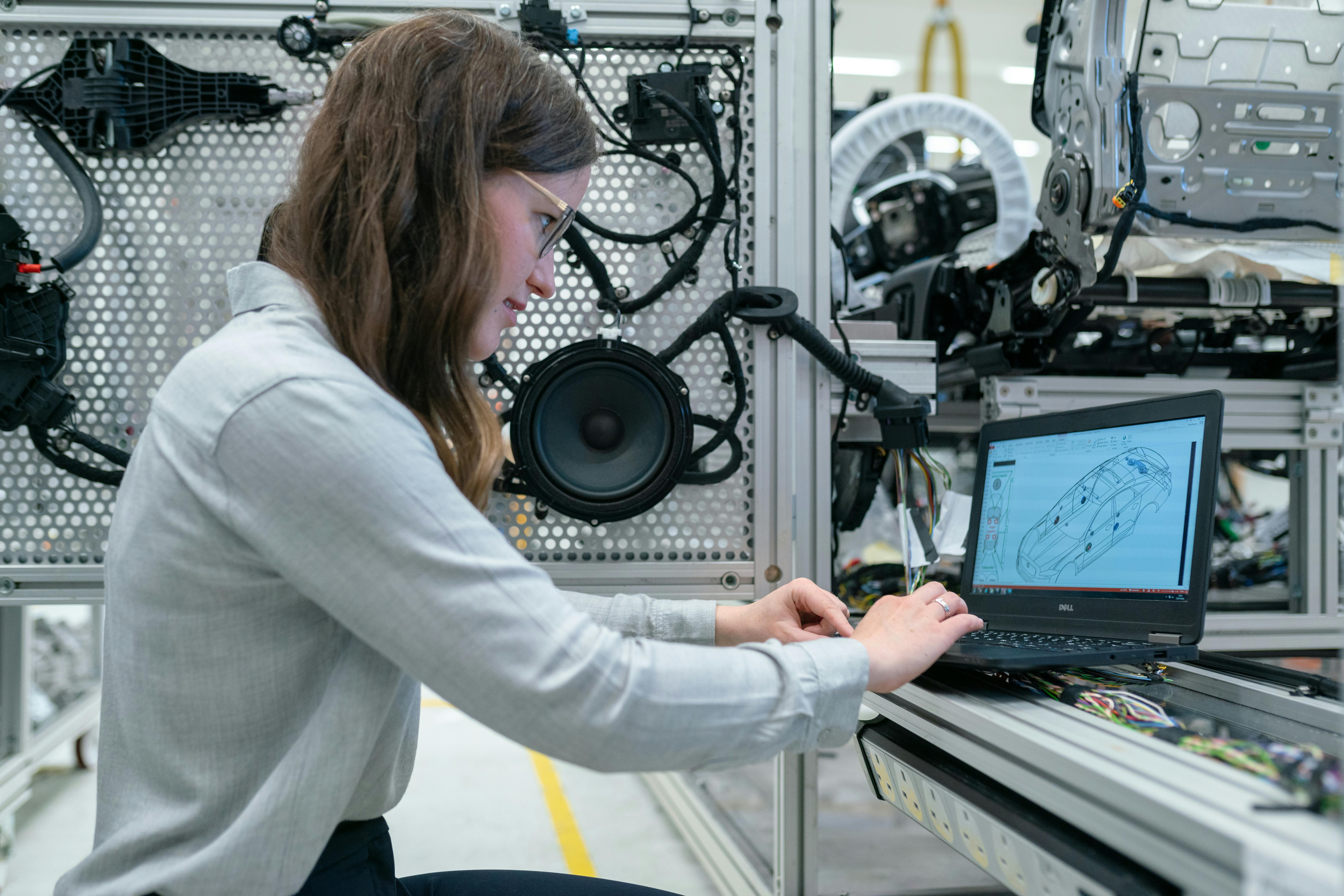

A complex end-of-line tester is more advanced than a simple test tower in that this equipment will house moving contactor units, drawer systems and the so-called jigs, in which products can be tested.

In this case, too, it can be said that the planning of instruments and electric hardware – test hardware – can be performed relatively simply and at a reasonably short expenditure of time.

The larger part of the planning time must be spent on the moving or static pin beds connected to the product and the nesting receiving the product; the other works need less attention. Depending on the project, from a system containing but a few nests to large ones with 16-20 nests, complexity of the work may vary over a wide range.

Summarising the above, more complex end-of-line testers include everything that may be necessary for testing a product.

At ProDSP, today we can say we have solutions for all requirements ranging from end-of-line testers that can be integrated into production lines to stand alone variants.

Author:

Dombi Gábor, mechanical techleader