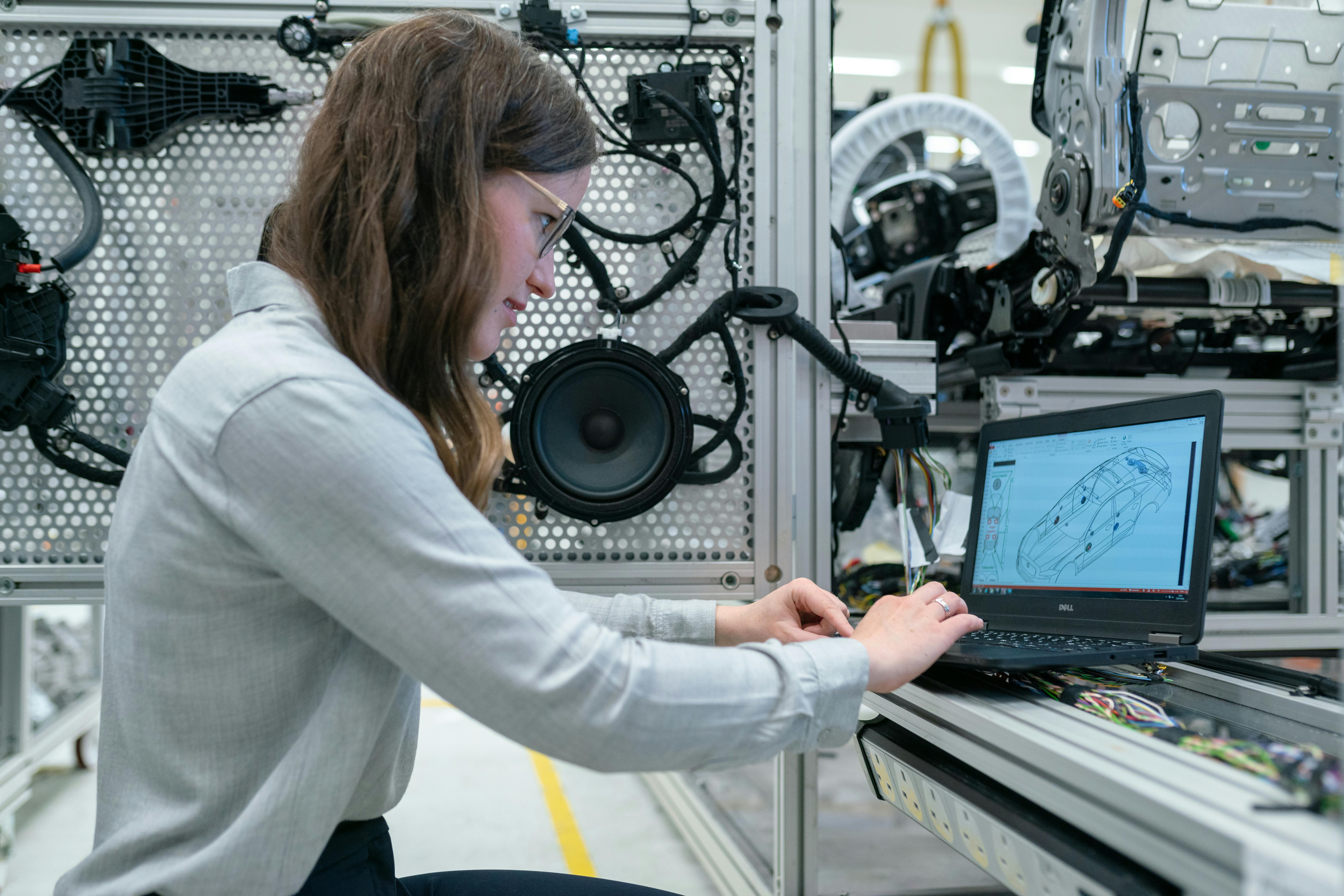

Methods of electrical design in industrial testing (EPLAN)

Many people first encounter the term ‘current flow diagram’ when studying for an engineering degree. At that stage, they have no idea how important that knowledge will be later when they work on real-life industrial projects. The designer software market is full of excellent products. The software of choice of the electrical designer team of ProDSP is EPLAN Electric P8. This system has a comprehensive and constantly updated database. Hence, it is suitable for quick and precise designing. The macro database-driven customization of pages also gives an excellent opportunity to accelerate the design process.

In this article, we shed light on the methods of electrical design in industrial testing as we at ProDSP do it.

Process steps

The first thing we need is the exact specification. This lets us know what the client needs. Once that is confirmed, the next step is to create a new, empty project with the so-called report sheets.

In the next step of the design, we need a device grid and a database that contains the detailed data of the parts to use. The size of horizontal and vertical spacing of our preferred device grid is 28mm.

The devices and terminal blocks are placed onto these lattice points. Therefore, when switching between plot frames, the drawing will make up a coherent whole. Not only does this make the drawing look elaborated, it also suggests true professionalism. It is also recommended to use 1, 2, and 4-mm grids, and smaller drawing components too.

Design methods

Once the lattice points have been defined, it is recommended to choose the design method. This will be influenced by the given specification. There are two major design methods: device-oriented and function-oriented design.

During device-oriented design, the signals connecting to a given device are stopped but the device is not disassembled. However, during function-oriented design, it is recommended to arrange signals related to one given function onto one page. An example for this is a star delta motor start. In this case, the motor, its contactors, the PLC control signals, the feedback lights, the relays and the auxiliary contacts can all be displayed on one page.

Beside the display view of the pages, grouping the pages is also an important aspect in order for the page to be as clear and easy to use as it is for the design engineer.

It is crucial to know the specification of the equipment to design before the design process starts as choosing the right design method makes the design easier whereas choosing another one makes it more difficult.

Grouping

We, at ProDSP, usually use two grouping methods: grouping according to power supply chain or function.

Grouping by power supply chain, we start at the entry point and move towards the direction of the end use, i.e. most frequently the product to test. In this case, design is made more difficult as the equipment’s manual user elements are spread across the design. Therefore, by breaking this structure, these elements can be placed on pages 2 to 5 following the power supply entry together with the safety control module.

Whenever we have had to repair the equipment of another manufacturer throughout our professional history, this has always been the first relevant piece of information as this makes it clear which parts become voltage-free once the emergency button is pushed.

This design method may also allow for the equipment to be more easily used and repaired by technicians, repairers and service engineers. In certain cases, grouping by function is also suitable for the creation of easy-to-understand drawings, however, grouping is often subject to question if there is an overlap among functions. For example, the safety control module, the PLC and the Switch may all have Ethernet and Profinet ports. Therefore, these can belong to safety devices, 24V control and to the information technology system too.

Efficiency

Beside good quality visualization, ProDSP also puts great emphasis on efficiency. Thanks to its flexibility, the company can work to short deadlines too which means that to increase the efficiency on the device side is an important factor. EPLAN’s developer environment is excellent for this purpose too. Apart from developing the parts database used by the electrical design team, increasing emphasis is laid on developing the macro database, and using frequently used and recurring pages and elements in order to decrease the number of drawing errors and make the design process simpler and quicker.

Using the macro database is an enormous task full off challenges, however, this knowledge and database has the potential to become the foundation stone of the electrical design team on the long term, ready to be benefitted from by all existing and future engineers.

The uploaded version of these databases is usually not public. Companies develop these for themselves based on their previous jobs and experience. The database can provide a perfect knowledge base for the engineers and can help the new recruits pick up the adopted drawing style, hence speeding up integration into the team.

Written by:

Szilágyi Levente, electrical design engineer